Creating an industrial floor on reinforced ground

Creating an industrial floor on reinforced ground

by Eric Laveder, Monofloor Design Chief

The search for optimised technical solutions remains an important driver of innovation for businesses. Therefore, specialist businesses have been working to develop ground reinforcement solutions in order to create concrete bases over soil with varying degrees of compressibility, to limit consolidation and avoid suspended flooring solutions. However, while this technique has the advantage of preventing almost all consolidation, production costs are high.

Vibro stone columns

For a long time, vibro stone columns have been considered the ideal means of improving the soil’s mechanical conditions. They reduce consolidation while maintaining a degree of flexibility. It is therefore possible to use conventional paving over the top of this type of reinforcement. Unfortunately, it is not possible to use them:

- on less favourable soil types (for example peaty soils) - if the soil cannot retain the material used to form the pillar, there is a risk of movement.

- in the case of major consolidation. The latter are reduced by a factor of 2 or 3 at most.

Rigid inclusions

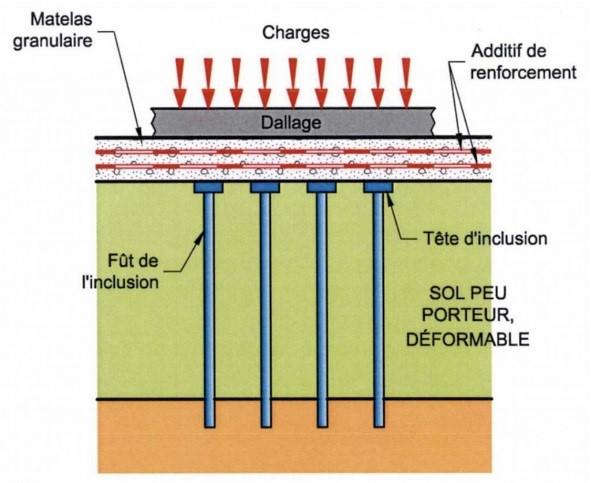

Rigid inclusions have been developed to prevent these issues (diagram 1). As the name suggests, this technique involves inserting rigid vertical elements into the compressible layers, following a regular grid of 3.00 x 3.00m maximum. These interact with the soil through friction. They have a greater compaction limiting effect than vibro stone columns.

However, inclusions are made of concrete or mortar and their elasticity modulus can be 5 to 7000 MPa, considerably higher than that of the existing ground. This makes it impossible to calculate the dimensions of the paving as if it was laid on a uniform surface, as this simple model no longer applies.

By way of analogy, imagine a sponge pierced by several toothpicks. When you push down on the surface of the sponge with your hand, you would easily feel the presence of these inclusions. The same thing happens with paving. It is possible to reduce the “hard spot” effect by increasing the thickness of the load distribution layer between the paving and the top of the inclusions, but in practice its thickness is limited and is not sufficient to create a level platform.

ASIRI recommendations

In light of this, it is essential to take into account the effect of the additional moments generated by soil reinforcements on the paving. The major challenge lies in calculating these additional demands. In this sense, the ASIRI (Amélioration des Sols par Inclusions Rigides) recommendations are a valuable, if not indispensable, resource. This document is the result of a French national research project led by IREX with the cooperation of industry professionals (research laboratories, control offices, ground reinforcement companies, industrial flooring companies). It was published in 2012 and its implementation has been mandatory in France since 1 October 2012. The main points of these recommendations are as follows:

- The additional efforts are significant and must be assessed using the calculation methods provided by the ASIRI recommendations. The moments resulting from the presence of inclusions are proportional to the grid size and inversely proportional to the mechanical characteristics of the ground and the thickness of the load distribution layer. Failure to properly account for the presence of inclusions can lead to damage (see image 2).

- There is a need for cooperation between ground reinforcement, industrial flooring and groundworks companies. The project manager is responsible for bringing together all elements of the design and distributing this information to all companies involved. The use of rigid inclusions for soil reinforcement brings together the paving, the platform, the rigid inclusions and the natural ground, which work together as a single, inseparable whole. All companies should plan their respective work using shared data.

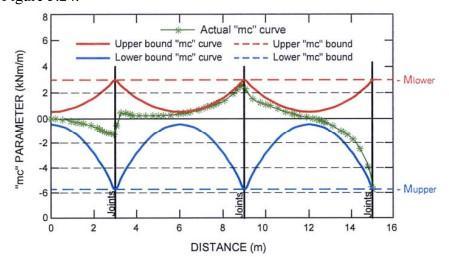

- The ground reinforcement company provides the stresses (in kN.m/m) resulting from the use of inclusions and their interaction with any potential joints in the paving (see diagram 3). In certain cases, if necessary due to the nature of the soil reinforcements, the paving must therefore take the form of a suspended floor.

Latest Technical Advice and Articles

Disrputive face joints - a review

Formed construction joints are widely accepted to be the weakest ...